The SIDEWINDER Self Timing Brake is not just another knockoff copy of existing self timing brakes. Â It was engineered from the ground up to be extremely effective, easier to install, and much more versatile. The SIDEWINDER uses the same patent pending self timing technology as the HELLFIRE, only larger. Read more on all of its advantages below:

Caliber Selection

In order to simplify the choices, we have three caliber selections available for the SIDEWINDER brake. The difference in efficiency between using a caliber specific brake bore, and the next size up is very minimal, so we decided to simplify things in order to lower overall costs to you the consumer. As you can imagine, trying to stock the exact quantities required of six or so different calibers would be impossible.

30 Cal Good for any bullet caliber up to and including 0.308, ie 223, 6mm, 6.5mm, 7mm

338 Cal Good for any bullet caliber up to and including 0.338

375 Cal Good for any bullet caliber up to and including 0.375

Notable Features

Extremely easy installation, brake WILL NOT turn as you torque the collar to lock. No more guessing where the brake ports will line up once you tighten it down!

Simple round knurled nut that requires no tools to time the brake.

Return to zero is excellent. This means removal of your brake and re-installation will not require a zero change.

Suppressor mounts like those available for the HELLFIRE will be available soon.

Simply torque the universal adapter onto your barrel with a 13/16 wrench, this piece never has to come off. Next, LEFT HAND thread the brake/collar assembly onto the adapter until it is almost snug. Now rotate the brake until it is level, push the brake into the adapter and you will feel it lock onto the taper. Now tighten the collar fully by hand, and you are done!

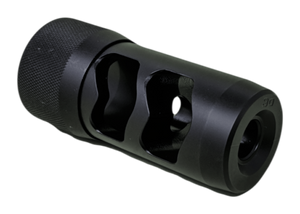

SIDEWINDER Muzzle Brake

Rearward facing ports for the ultimate in recoil reduction. The SIDEWINDER is modeled after our extremely popular HELLFIRE brake, which was independently tested side by side with the best brakes on the market. The HELLFIRE showed 52% recoil reduction on a 6.5 Creedmoor test rifle. This is ~4% more than the one of the most popular brakes on the market. The SIDEWINDER has one more port and is larger in diameter so you can expect a notable increase in recoil abatement.

Proprietary port design controls muzzle rise without the use of top porting.

Proprietary progressive port design. The amount of work done by a muzzle brake as you move away from the muzzle decreases with distance. Knowing this, we decided to increase the size of the first port and decrease slightly with every port further out. This keeps the overall length down, without sacrificing efficiency.

Face of brake is engraved with caliber to indicate the top for correct orientation, and a horizontal line to aid in leveling.

Made from heat treated 17-4PH Stainless Steel

Brakes will be available in Black Nitride finish or raw stainless (all universal adapters will be black)

Manufactured on state of the art CNC Machines right here in NW Ohio.100% Made in USA.

1.125 OD Brake, 1.275 OD collar

Universal Adapter These will be available separately after this initial run of brakes.

Universal adapter system allows TOOL FREE use of multiple muzzle attachments

Universal adapter uses a taper surface similar to a machine tool spindle for the absolute best alignment with the muzzle threads.

Universal adapter is made in one operation on a state of the art CNC lathe, threads are 100% concentric to taper surface

All Universal Adapters will come Black Nitrided to prevent galling.

Available in 5/8-24 class 3, 3/4-24 class 3, M18x1 6g, and M18x1.5 6g

Maintenance

Maintenance on any muzzle brake is essential. Just like your barrel, muzzle brakes need cleaned. Over time carbon will build up in the ports, mainly the third and last port as the first two are semi-self cleaning from the muzzle blast. When this carbon builds up, it will eventually get to the point that bullets can actually strike it. Depending on your shooting regimen you may not notice this, you might just call it a flier. But in a competition when you need every round to impact, this is critical. Carbon bullet strikes are a worst case scenario, but the buildup can also cause accuracy or POI issues just due to airflow changes in the brake ports.

- The best cleaning method for any muzzle brake is PREVENTATIVE MAINTENANCE. Â If you clean the brake every time you clean the barrel (200-400 round intervals, shorter for 6mm rounds) it will make your life much much easier. With that being said, just soak the brake in a carbon cleaner like Boretech C4 and all the carbon should come right out, especially if you have a Black Nitride brake. Raw stainless brakes can be more challenging to clean because the surface is more porous. If necessary, you can use any kind of cleaning brush to aid in the removal of carbon from the ports. Black Nitride is harder than any material they attach to a brush, so you will not scratch the surface. Â Raw stainless may scratch if you use a stainless or other harder bristle brush.

- If you decide to wait until 1000 rounds or more, you will have a lot of carbon buildup in the 2nd, 3rd, and 4th port which will take some effort to remove. Best method here is probably to soak for a day or two in C4 and use a pick to get the big chunks out. Then follow the above method to get the remainder off.

- You should also clean your Universal Adapter with the same care. Every time you clean your barrel, let the carbon cleaner from patching the barrel soak on the muzzle for a few minutes and use a q-tip to wipe any carbon from the barrel crown and inside the end of the adapter. Â Soak a patch in carbon cleaner and wipe the taper surface of the adapter off. If there is persistent carbon on the surface, use steel wool to remove, it will not damage the surface.